You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

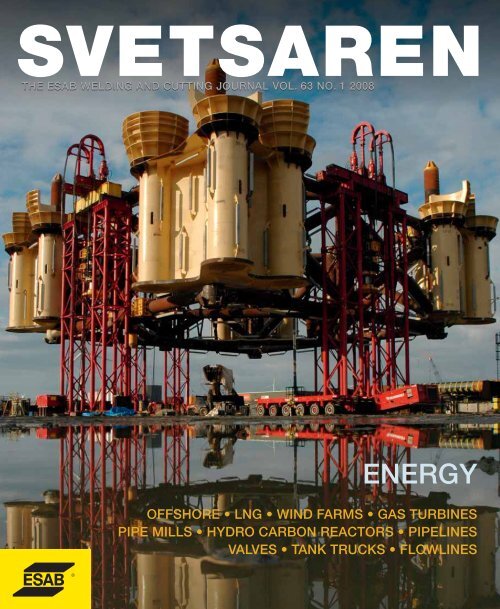

THE ESAB WELDING AND CUTTING JOURNAL VOL. 63 NO. 1 <strong>2008</strong><br />

ENERGY<br />

OFFSHORE • LNG • WIND FARMS • GAS TURBINES<br />

PIPE MILLS • HYDRO CARBON REACTORS • PIPELINES<br />

VALVES • TANK TRUCKS • FLOWLINES

Box Information.com<br />

Setting new standards<br />

We have now gained<br />

OHSAS 18001 group<br />

certification from DNV.<br />

Our group Environmental,<br />

Health & Safety<br />

Management System<br />

was already ISO14001<br />

certified. This is believed<br />

to be the most comprehensive<br />

certification<br />

achieved by any global<br />

company to date.<br />

It includes all production<br />

operations, sales and<br />

central functions within<br />

ESAB at 1 July 2007.<br />

Our system will benefit<br />

our customers<br />

It does not matter if our customers operate in China, Germany, US, Brazil<br />

or Sweden. Wherever in the world you buy ESAB products, these are<br />

produced in accordance with the same global EHS standards where<br />

occupational and product health & safety always comes first. Let us show<br />

you what a well managed company can do for you!<br />

www.esab.com

<strong>Svetsaren</strong><br />

ENERGY<br />

Articles in <strong>Svetsaren</strong> may be reproduced<br />

without permission, but with an<br />

acknowledgement to ESAB.<br />

Publisher<br />

Johan Elvander<br />

Editor<br />

Ben Altemühl<br />

Editorial committee<br />

Tony Anderson, Klaus Blome, Carl Bandhauer,<br />

Christophe Gregoir, Joakim Cahlin, Dan<br />

Erlandsson, Björn Torstensson,<br />

Nils Thalberg, Annika Tedeholm,<br />

José Roberto Domingues, Antonio Couto Plais.<br />

Address<br />

<strong>Svetsaren</strong><br />

ESAB AB Central Market Communications<br />

Box 8004<br />

S-402 77 Gothenburg<br />

Sweden<br />

Dear reader,<br />

Energy makes the world tick. Its generation and<br />

supply is a significant factor in global development,<br />

having an intimate effect on life style and quality. The<br />

lack of energy availability in many parts of the world,<br />

the growing awareness of the necessity to manage the<br />

limited resources and excessive and sometimes<br />

wasteful human behaviour, all create a challenge for<br />

the future.<br />

The limited availability of fossil fuels and their harmful<br />

effect on our environment, forces us to develop<br />

HARALD HESPE<br />

renewable forms of energy and, also, to explore the still<br />

enormous potential savings we can make in energy consumption. The latter is an integral<br />

element of ESAB’s environmental management system- rewarded with the ISO 14001<br />

global environmental certification.<br />

Our energy efficiency ratio in production sites and offices (revenues/energy use), for<br />

example, has doubled in 10 years (1996-2006) – as a result of focused and planned<br />

activities - and we intend to double this again in the coming decade. Another of our<br />

long- term strategic objectives is to significantly increase the use of energy from<br />

renewable sources (now 5%). This corporate policy guides our development efforts and<br />

demonstrates that leading industrial enterprises can take the initiative and can change<br />

traditional behaviour.<br />

Internet address<br />

http://www.esab.com<br />

E-mail: svetsaren@esab.com<br />

Printed in The Netherlands by True Colours<br />

The exploration of fossil fuel based resources has accelerated and taken on a new path<br />

in commercialising previously non-economic areas. Exploration takes place in more<br />

remote areas, more challenging environments in terms of climate and we are exposed to<br />

deep sea drilling and many more difficult engineering challenges. Wind power has<br />

become a global priority and we see renewed worldwide investment in nuclear power<br />

generation.<br />

THE ESAB WELDING AND CUTTING JOURNAL VOL. 63 NO. 1 <strong>2008</strong><br />

Lifting of the<br />

Tombua Landana<br />

platform template<br />

at Heerema,<br />

Vlissingen,<br />

The Netherlands.<br />

This issue of <strong>Svetsaren</strong> features articles and application stories that illustrate the success<br />

of our clients and the deep involvement of ESAB as a welding and cutting solution<br />

provider for the energy generating industry.<br />

Good reading,<br />

ENERGY<br />

OFFSHORE • LNG • WIND FARMS • GAS TURBINES<br />

PIPE MILLS • HYDRO CARBON REACTORS • PIPELINES<br />

VALVES • TANK TRUCKS • FLOWLINES<br />

HARALD HESPE<br />

MANAGING DIRECTOR ESAB MIDDLE EAST FZE

Excellence in wind<br />

tower welding<br />

Competitiveness in wind tower fabrication<br />

is synonymous with the application<br />

of productive, high quality welding<br />

solutions. With ESAB, you are assured of a<br />

partner who understands your challenges<br />

and responds with innovative welding and<br />

cutting technology.<br />

We design and retrofit column & boom<br />

stations for submerged arc welding of<br />

circumferential and longitudinal<br />

welds – including head and tailstock,<br />

automation and integration in existing<br />

production lines. These are complemented<br />

by welding tractors and equipment for<br />

special components.<br />

Tandem - twin technology is our latest<br />

development in multi-wire welding heads<br />

providing unsurpassed deposition rates<br />

and welding productivity.<br />

Developed specifically for your industry,<br />

our flux/wire combinations ensure the<br />

required weld quality and mechanical<br />

properties - be it for land-based, offshore<br />

or even arctic wind towers.<br />

Visit us at www.esab.com

Contents<br />

07<br />

15<br />

18<br />

23<br />

26<br />

32<br />

34<br />

37<br />

Template for monster platform challenges<br />

Heerema.<br />

ESAB low-hydrogen consumable technology<br />

crucial in safe and productive welding.<br />

Port of Marseille sees LNG storage tanks<br />

erected with ESAB welding technology.<br />

Project, awarded to a joint venture of<br />

Saipem and Sofregaz, sub-contracted to<br />

the Italian Bentini Group SpA.<br />

SIF Group bv at the foundation of Dutch<br />

wind energy<br />

ESAB SAW technology crucial in the<br />

production of piles and transition pieces<br />

for the Q7 North Sea wind farm.<br />

Zorya-Mashproekt relies on ESAB for arc<br />

welding of gas turbine components<br />

Zorya-Mashproekt is a leading Ukranian<br />

producer of industrial and marine gas<br />

turbine power plants and engines.<br />

Complete and reliable partner for pipe mills.<br />

The latest ESAB equipment and consumables<br />

for longitudinal welding.<br />

Paresa SpA construct spheres for the<br />

Kuwait petrochemical industry<br />

Part of integrated petrochemical plant for<br />

hydrocarbons processing.<br />

ESW Inconel strip cladding<br />

Solution to clad steel shortage for<br />

Maritime Industrial Services, Dubai.<br />

Mechanised pipeline welding in the<br />

Saudi desert<br />

Magnatech orbital welding system and<br />

ESAB cored wire do the job.<br />

41<br />

43<br />

47<br />

51<br />

Cladding of valves for petrochemical<br />

plants.<br />

Valve manufacture and repair is a growth<br />

industry.<br />

Techint and ESAB Brazil - partners in the<br />

construction of the PRA-1 jacket.<br />

Technical partnership fundamental to the<br />

success of the project.<br />

Manufacture of mobile gasoline tanks in<br />

AlMg5 alloy at ZAO BECEMA, Russia.<br />

ESAB assists in conversion from steel to<br />

aluminium.<br />

Belleli Energy SpA reactors at the heart of<br />

Qatar’s Pearl Gas-to-Liquids Plant.<br />

ESAB arc welding consumables deliver<br />

quality and productivity.<br />

High integrity flowline welding at LMI<br />

56 ESAB orbital TIG technology crucial.<br />

58<br />

Product News<br />

• New power sources for orbital welding<br />

• Robust and powerful MIG/MAG Power<br />

sources for heavy duty welding<br />

• Caddy - the portable solution for<br />

professional welding<br />

• New Origo welding machine for<br />

demanding applications<br />

• Reactive welding helmets<br />

• AUTOREX – The first, totally encapsulated,<br />

automatic plasma cutting centre<br />

• Tramtrac TM II – flexible solution for the<br />

repair of embedded city tramway rails.<br />

• New submerged arc fluxes<br />

• OK Tubrod 14.11 – Metal cored wire<br />

for high speed thin plate welding<br />

• VacPac gets slimmer

6 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

Template for monster platform<br />

challenges Heerema.<br />

ESAB low-hydrogen consumable technology crucial in safe<br />

and productive welding.<br />

ALFRED VAN AARTSEN, HEEREMA VLISSINGEN B.V., THE NETHERLANDS AND ERIC DE MAN, ESAB NEDERLAND B.V., AMERSFOORT, THE NETHERLANDS.<br />

Thicker and heavier, and with<br />

sharper tolerances than ever<br />

before – this was in essence the<br />

challenge Heerema Vlissingen<br />

faced in the construction of the<br />

template for the Tombua Landana<br />

oil and gas platform. The answer<br />

was found in smart logistics and<br />

precision work, supported by<br />

proven welding solutions. (See<br />

page 14 for a description of the<br />

Figure 1. The tower base template TBT (grey), the tower bottom section TBS (brown) and the foundation piles.<br />

Tombua Landana project).<br />

Acknowledgement<br />

We thank Heerema Production Manager, Harm<br />

Sanstra, for facilitating our visits to the Vlissingen yard.<br />

Heerema Fabrication Group (HFG)<br />

Heerema is a name that requires little explanation<br />

– especially not for <strong>Svetsaren</strong> readers in the oil<br />

and gas industry. It is one of the bigger, globally<br />

operating players in the engineering and fabrication<br />

of large and complex structures for the oil<br />

and gas industry. It has been active in the<br />

offshore industry ever since oil and gas were<br />

discovered in the North Sea in the early 1960’s<br />

and enjoys a reputation for state-of-the-art<br />

engineering, fabrication and project management.<br />

HFG has yards in the Netherlands (Vlissingen and<br />

Zwijndrecht) and in the United Kingdom<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 7

(Hartlepool). All are equipped with large prefabrication<br />

and assembly halls for indoor<br />

construction and are capable of handling large<br />

projects, simultaneously.<br />

HFG is part of the Heerema Group, together with<br />

Heerema Marine Contractors (HMC) which transports,<br />

installs and removes offshore facilities, and<br />

INTEC engineering, which provides engineering<br />

services to the energy industry. HFG Engineering,<br />

a subsidiary of HFG with offices in New Orleans<br />

and Houston, specialises in on- and offshore<br />

facility designs.<br />

All Heerema companies operate an integrated<br />

management system that complies with ISO 9001:<br />

2000 (Quality Management Systems), ISO 14001:<br />

2004 (Environmental Management System) and<br />

OHSAS 18001: 1999 (Occupational Health and<br />

Safety Management System) standards.<br />

The Tombua Landana template<br />

The tower base template (TBT) has a surface area<br />

of forty by forty metres, is 24 metres high and<br />

weighs 3,000 tons. It includes 12 main foundation<br />

piles with a total weight of 9,500 tons. It was completed<br />

and shipped to Angola in December 2007.<br />

Figure 1 shows a sketch of the TBT. The principal<br />

components are the pile sleeve clusters, the rows<br />

and the leveling jacks. Not indicated, but<br />

discussed later in this article, are the lifting<br />

trunnions – used for dual crane lifting with one of<br />

HMC’s specialised barges.<br />

The pile sleeve clusters form the cornerstones of<br />

the TBT. They guide the twelve foundation piles<br />

which are driven through them into the sea bed.<br />

Crucial during installation of the 190 m long piles in<br />

nearly 400 m deep waters, are the open cones on<br />

top of the pile sleeves. They catch the foundation<br />

piles hanging from the crane and guide them into<br />

the sleeves, after which pile driving commences.<br />

Part of the length of all foundation piles remains<br />

extended above the pile sleeves. The Tower Base<br />

Section – the lower part of the tower – is placed<br />

over them and secured to the template.<br />

The rows are a network of heavy pipes connecting<br />

the four pile sleeve clusters to form a rigid<br />

construction. Four leveling jacks, devices to<br />

position the template horizontally with great<br />

accuracy, are attached to the central columns of<br />

the rows. The shim piles on the leveling jacks rest<br />

on leveling piles in the sea bed. Leveling is<br />

performed by jacking the template up or down<br />

relative to the shim piles.<br />

The entire Tombua Landana project is characterised<br />

by very narrow construction tolerances, the<br />

substructures being placed on top of each other,<br />

in nearly 400 m deep waters - a particularly<br />

unforgiving environment for any misalignment.<br />

Also, the TBT was subject to strict dimensional<br />

tolerances – up to three times more precise than<br />

normally required in offshore fabrication.<br />

Moreover, it was the first part of the tower and all<br />

eyes were focused on Heerema. Two Daewoo<br />

representatives and two representatives of<br />

Chevron supervised the project and carried out<br />

regular inspections.<br />

Table 1. Mechanical requirements WPQ for type I and II steels.<br />

Steel grades, mechanical requirements and<br />

preheat temperatures<br />

Steel grades were purchased according to the<br />

“General Specification 1.14 Structural steels and<br />

other materials”, issued by the Cabinda Gulf Oil<br />

Company for the projects in block 14. In this<br />

specification, material types are ranked I and I-X,<br />

II and II-X, III, IV and V. Material types I are for structural<br />

members and tubular joint cans which are<br />

fracture critical and material types II are for structural<br />

members and cans where failure would pose a<br />

threat to the structure. Material types III, IV and V<br />

are for non-critical components. A list of valid steel<br />

classifications is given for each material type.<br />

Heerema Vlissingen purchased various types of<br />

plate according to EN 10225 Grade 355 (thermomechanically<br />

controlled rolled) and API 2MT1 as<br />

rolled, covering the demands of material types<br />

I and II, and meeting special constructional<br />

requirements such as “through thickness<br />

properties”. All main steel was purchased from<br />

Dillinger Hüttewerke in Germany.<br />

Mechanical weld requirements are established by<br />

Cabinda’s General Specification 1.15 – Structural<br />

welding and inspection. Charpy V-notch impact<br />

testing of both weld metal and heat affected zone<br />

was required on all welding procedure qualifications,<br />

with notch locations at the weld centre line, fusion<br />

line and FL+2mm. CTOD testing of the WM and<br />

HAZ was required for type I and II steels with a<br />

thickness greater than or equal to 63 mm (2.5”),<br />

to be performed on the thickest steel to be<br />

welded while using the highest preheat and<br />

interpass temperature permitted by the welding<br />

procedure to be qualified.<br />

Table 1 gives an overview of CVN and CTOD<br />

requirements. An additional cross weld zone hardness<br />

requirement was set at HV10 325 maximum.<br />

In constructions such as these, involving thick<br />

material, the prevention of hydrogen induced<br />

cracking (cold cracking) is essential. This starts<br />

with the purchase of steels with limited<br />

hardenability. Cabinda’s General Specification<br />

1.14 for structural steels and other materials<br />

therefore specifies a maximum Pcm value of 0.23<br />

(extended CE formula).<br />

In welding, preheating, along with the use of<br />

low-hydrogen consumables, is essential in the<br />

prevention of cold cracking. Cabinda General<br />

Specification 1.15 refers to AWS D1.1, for<br />

preheat and interpass temperatures to be applied.<br />

CVN<br />

CTOD<br />

Steel type minimum average minimum single thickness minimum<br />

I 34J/-40ºC 27J/-40ºC 76mm (3”)<br />

0.38mm/-10ºC<br />

II 34J/-18ºC 27J/-18ºC 76mm (3”)<br />

0.38mm/-10ºC<br />

8 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

Table 2. Preheat and interpass procedure.<br />

Thickness Preheat Interpass<br />

good CVN properties down to -60°C and is<br />

CTOD tested in the AW and SR condition. It has<br />

a vast track record that dates back to the years<br />

when MMA was the standard for manual welding<br />

in offshore fabrication. FILARC 76S is low-hydrogen<br />

with low moisture absorption properties. It is<br />

supplied to Heerema Vlissingen in VacPac vacuum<br />

packaging for ultimate protection.<br />

Table 3. Overview of low-hydrogen consumables used for the Tombua Landana template.<br />

ESAB consumables EN classification AWS Classification<br />

FILARC PZ6125 758: T 42 6 1Ni B M 1H5 5.29: E71T-5G<br />

FILARC PZ6138 758: T 46 5 1 Ni P M 1 H5 5.29: E81T1-Ni1MJ H4<br />

OK Flux 10.47/ OK Tubrod 15.24S EN: S 46 5 AB T3Ni1 (AW) 5.23: F8A4-EC-G (AW)<br />

FILARC 76S 499: E 42 6 Mn1Ni B 32 H5 5.5: E7018-G<br />

Major welding applications in the<br />

pile sleeve cluster<br />

Figure 3 shows the fabrication of a pile sleeve<br />

cluster. Its main components are indicated. The<br />

pile sleeve - the part which guides the foundation<br />

piles - has been pre-fabricated by Sif Group bv, in<br />

Roermond, along with the foundation piles themselves.<br />

Also the parts of the conical “pile catcher”<br />

allowing the use of SAW - mostly circumferential<br />

welds - are already attached during pre-fabrication.<br />

Heerema Vlissingen completes the catchers with<br />

stiffener plates (Figure 4). This involves a vast<br />

amount of full penetration butt welds, as well as<br />

fillet welds, all performed with manual FCAW, using<br />

FILARC PZ6138. Where possible, root passes are<br />

deposited on ceramic weld metal support.<br />

The welds connecting the pile sleeve to the shear<br />

plate involve a symmetrical double-sided K-joint in<br />

51 mm thickness (openings angle 40 degrees,<br />

root gap 5mm, root face 1mm), welded with the<br />

SAW process, using the OK Flux 10.47/OK<br />

Tubrod 15.24S flux/wire combination and ESAB<br />

A2 welding tractors. The root pass of these full-penetration<br />

welds is done with PZ6125, on ceramic<br />

backing, whereas sufficient thickness for the SAW<br />

process is obtained by a hot pass with PZ6138. In<br />

this stage, the construction can still be turned on<br />

roller beds, aided by contra weights, in order to use<br />

the productive SAW process on both sides.<br />

Turning the construction is no longer possible<br />

when two pile sleeve-shear plate pairs – grit<br />

pile sleeve<br />

catcher<br />

shear plate<br />

lower yoke plate<br />

upper yoke plate<br />

main leg<br />

Figure 3. Fabrication of a pile sleeve cluster.<br />

10 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

Figure 4. FCAW of the sleeves – the part that catches<br />

the foundation pile.<br />

Figure 5. Submerged arc welding of a sheer plate onto<br />

a pile sleeve.<br />

Figure 6. Lay-out of a row on the factory floor before<br />

welding – a precision job.<br />

blasted and painted - are connected to the main<br />

leg. Here a combination of SAW for the downhand<br />

side and FCAW for the overhead side is<br />

used (root FCAW on backing). The preparation is a<br />

2/3 –1/3 K-joint, so that the larger part of the joint<br />

volume can be welded in the downhand position<br />

with the productive SAW process. The 1/3 side is<br />

completed in the overhead position, using<br />

FILARC PZ6138 rutile cored-wire.<br />

When the shear plate of the third, and last pile<br />

sleeve in a cluster, is connected to the main leg,<br />

the joint position is horizontal-vertical. The joint<br />

preparation is again a symmetrical K-joint welded<br />

completely with the FCAW process, using FILARC<br />

PZ6138.<br />

The upper and lower yoke plates are connected<br />

by means of manual FCAW. It concerns full<br />

penetration X- and K-welds with all welding<br />

positions occurring. Again PZ6138 is the main<br />

consumable (roots on ceramic backing).<br />

TKY-joints in rows<br />

The rows - a network of heavy pipes connecting<br />

the four pile sleeve clusters – are pre-fabricated<br />

both indoors and outdoors. Their lay-out on the<br />

factory floor (Figure 6 ) exemplifies the great<br />

dimensional precision required.<br />

The two columns on the left and right are not part<br />

of the structure. They have the same dimensions<br />

as the main legs of the pile sleeve clusters and<br />

precisely set the dimensions of the row, before<br />

(tack) welding. Permittable deviations here are as<br />

narrow as ± 1/4” (6 mm) horizontally and<br />

± 1/8” (3 mm) vertically, requiring extreme<br />

accuracy. It is a procedure of virtually endless<br />

dimensional control. The same procedure is<br />

repeated during erection of the template<br />

(Figure 7), before rows are finally connected to the<br />

legs in the pile sleeve clusters.<br />

Figure 7. Erection of the template. All rows are first carefully positioned within the tolerances – with the help of temporary<br />

columns (left) – before they are attached to the docking pins in the pile sleeve cluster (cluster visible in the background).<br />

All nodes (TKY-joints) are welded in the positions<br />

as they occur in figure 7 with FCAW using PZ6125<br />

for the root and PZ6138 for filling. Figure 8 shows<br />

the FCAW welding on a special TKY-joint – the<br />

lifting trunniuns. These are used to attach the lifting<br />

cables onto the template during installation. Part of<br />

it is welded with SAW with OK Flux 10.47/OK<br />

Tubrod 15.24S (Figure 9).<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 11

Figure 8. FCAW of a lifting trunnion.<br />

Figure 9. SAW on a lifting trunnion.<br />

Foundation piles<br />

The foundation piles are pre-fabricated by Sif<br />

Group bv, arriving in 83-93 m lengths. To achieve<br />

their final length of 170 –190 m, they need to be<br />

welded together (Figure 10 and 11). This is again<br />

done by FCAW with PZ6138, but here it is<br />

mechanised welding with ESAB Railtrac equipment.<br />

The joint configuration is adapted to this<br />

method -an unsymmetrical X-joint with most of<br />

the weld volume on the outside. The inside part is<br />

welded manually, vertically-up. The root pass is<br />

deposited on ceramic backing. After removal of<br />

the fit-up plates, the majority of the weld volume<br />

is mechanised welded from the outside, verticallyup<br />

from 6 to 12 ‘o clock, mostly with a slight<br />

weaving motion. Welding parameters are adapted<br />

to the several clock positions by the operators.<br />

Dimensional control and weld finish<br />

Normal offshore fabrication, eg, a jacket on top of<br />

which the deck and operational facilities are placed,<br />

is naturally, subject to strict dimensions, but it is<br />

more forgiving than in the case of the Tombua<br />

Landana project. The fact is that three<br />

substructures, fabricated by three different yards,<br />

are stacked on top of each other in almost 400 m<br />

deep waters - and simply have to fit. This places<br />

extremely high demands on the dimensional control<br />

– roughly 3 times as high as normally required.<br />

This is as equally valid for the fabrication of the<br />

TBT’s components – the pile sleeve clusters and<br />

the rows – as it is for the assembly of the super<br />

structure. To exemplify the dimensional control<br />

and its implications for welding, we return to the<br />

fabrication of the pile sleeve clusters, shown in<br />

Figure 12.<br />

This image shows the completed pile sleeve cluster<br />

and the nominal distances between the centre<br />

lines of the pile sleeves and the centre line of the<br />

main leg (5172.5 and 5173 mm). The maximum<br />

acceptable tolerance on these distances is 3 mm.<br />

A similar small tolerance is valid on the distances<br />

between the pile sleeves themselves, in the X and<br />

Y directions and on the mutual distances into the<br />

Z direction. This dimensional control is the key<br />

requirement, and everything else is subject to it.<br />

Ideally, the pre-fabricated yoke plates, including<br />

K-bevel, fit exactly, so that there is a constant<br />

root gap between the pile sleeves/main leg and<br />

Figure 10. Welding tents made from shrink foil protect the weld area from wind and rain.<br />

the yoke plate’s K-bevel. In practice, this is<br />

extremely difficult to achieve. Practically always, the<br />

root gap appears to be more or less eccentric. This<br />

must be corrected by grinding on the narrow side<br />

and buttering & grinding on the wider side<br />

– an extremely time consuming exercise.<br />

Measuring was performed by three parties;<br />

Heerema Vlissingen, Passe-Partout (independent<br />

contractor) and Chevron, who worked<br />

independently according to agreed measuring<br />

principles. Chevron were responsible for final<br />

measuring and reporting.<br />

Another time-consuming aspect was Class C and<br />

Class A grinding of weld surfaces. Grinding is<br />

done with an aluminium oxide based disc.<br />

Class C grinding is required for the TKY joints<br />

between the braces and the dummy leg (middle<br />

of the row) and between the braces and the main<br />

leg of the pile sleeve cluster. It is performed to<br />

correct excessive convexity, notches or undercut<br />

at the toes of the weld. The grinding of the toes<br />

of the cap must be performed to the point where<br />

a 1 mm diameter wire cannot pass between the<br />

disc and the plate (Figure 13).<br />

Class A grinding is performed on the welds connecting<br />

the lower yoke plates to the main legs of<br />

the pile sleeve clusters – at both sides of the<br />

K-joint. Class A means that weld profile is ground<br />

back to the theoretical radius. This is checked by<br />

using a template with a 45 mm radius, with a gap<br />

12 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

Figure 11. Vertically-up welding with ESAB Railtrac and<br />

FILARC PZ6138.<br />

Figure 12. Pile sleeve cluster dimensional control.<br />

the size of a paperclip not being allowed. The<br />

total length to be ground per weld was 2 x 11.5<br />

m for each of the four main legs.<br />

ISO 9001 and ISO 14001 approved world-wide.<br />

OHSAS 18001 is the latest approval obtained by<br />

ESAB, see page 2.<br />

Conclusion<br />

The Tombua Landana template was one of the<br />

most challenging projects ever undertaken by<br />

Heerema Vlissingen. It required a carefully<br />

planned factory lay-out and a level of precision<br />

not before experienced. The company finished<br />

the project within the agreed delivery term and,<br />

by the publication date of this <strong>Svetsaren</strong>, its sister<br />

company, HMC, will be involved in sea<br />

transportation and installation of the 474 m tall<br />

Tombua Landana oil and gas platform.<br />

The final words of this article should be<br />

addressed to the welders of Heerema Vlissingen<br />

who did such a tremendous job, notwithstanding<br />

the high preheat and interpass temperatures and<br />

overall tough working conditions.<br />

Figure 13. Class C grinding on TKY-joints to correct<br />

convexity, notches or undercut at the toes of the weld.<br />

Safety was essential. To step up its performance<br />

beyond already tough levels, Heerema Vlissingen<br />

took part in Chevron’s safety programme<br />

– Incident and Injury Free (IIF) – in which Chevron<br />

gave workshops and training to the yard personnel<br />

aiming at individual development.<br />

For its welding solutions, Heerema Vlissingen<br />

relied on low-hydrogen consumable technology<br />

from ESAB – a supplier that meets Heerema<br />

Vlissingen’s demands in any respect, including<br />

quality management systems, environmental<br />

management systems and occupational<br />

management systems. Like Heerema, ESAB is<br />

ABOUT THE AUTHORS:<br />

ALFRED VAN AARTSEN, EWE, IS WELDING ENGINEER AT<br />

HEEREMA VLISSINGEN B.V., THE NETHERLANDS.<br />

ERIC DE MAN, EWE, IS PRODUCT MANAGER<br />

CONSUMABLES AND KEY ACCOUNT MANAGER AT<br />

ESAB B.V., AMERSFOORT, THE NETHERLANDS.<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 13

Tombua Landana project<br />

This huge oil and gas platform is due to be operational by the third quarter of 2009 in the Tombua<br />

and Landana deep water development areas, off the coast of Angola. The main contractor is Daewoo<br />

Shipbuilding & Marine Engineering, on behalf of Cabinda Oil Company and its partners. It is the production<br />

centre in the development of the oil and gas reserves in block 14, in Angolan waters.<br />

The Tombua Landana development follows the installation of the Benguela Belize-platform, an integrated<br />

drilling and production platform for the development of the Benguela and Belize fields. It was the industry’s<br />

first application of compliant piled tower structural technology outside the Gulf of Mexico. At 512 m, it is<br />

among the world’s tallest man-made structures.<br />

The Tombua Landana project involves the construction of the drilling and production platform, a subsea<br />

centre of water injectors and producers and the installation and tie-in of two export pipelines that will<br />

connect the Tombua Landana drilling and production platform to the Benguela-Belize oil and gas pipeline<br />

transportation system.<br />

The Tombua Landana platform stands 474 m tall, nearly as high as her twin-sister in block 14. The<br />

platform engineering, fabrication and installation has been contracted to Daewoo Shipbuilding & Marine<br />

Engineering (DSME). DSME will build the the topside in Okpo, Korea and has subcontracted the tower top<br />

section (TTS) to Gulf Island Fabricators, the tower bottom section (TBS) to Gulf Marine Fabricators (USA);<br />

and the tower base template (TBT) to Heerema Vlissingen, The Netherlands.<br />

Transport of all substructures to Angola and installation has been subcontracted to Heerema Marine<br />

Contractors, a sister company of Heerema Vlissingen.<br />

Project Scope<br />

Landana North via<br />

Lobito Subsea<br />

Center C<br />

(3) Producers<br />

(3) Water Injectors<br />

18” TL OIL EXPORT<br />

PIPELINE<br />

Benguela Belize<br />

Platform<br />

14” TL GAS<br />

EXPORT PIPELINE<br />

16” BBLT GAS<br />

EXPORT PIPELINE<br />

T-L Drilling<br />

& Production<br />

Platform<br />

30 wells<br />

130 MBOPD Tombua South<br />

Subsea Center<br />

(6) Producers<br />

(4) Water Injectors<br />

Malongo<br />

Terminal<br />

East Kokongo<br />

Nemba<br />

T-L<br />

Project<br />

Scope<br />

Tower Top Section (TTS)<br />

6,700 t<br />

Images on project description page<br />

(+map to be added)<br />

Tower Bottom Section (TBS)<br />

29,200 t<br />

Tower Base Template (TBT)<br />

3,000 t<br />

Taipei 101<br />

1667ft (508m)<br />

Petronas Towers<br />

1483ft (452m)<br />

Wells Fargo<br />

994ft (303m)<br />

Bank of America<br />

781ft (238m)<br />

The Gherkin<br />

591ft (180m)<br />

Tombua Landana<br />

1554ft (474m)<br />

14 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

Port of Marseille sees LNG storage<br />

tanks erected with ESAB welding<br />

technology.<br />

BRUNO MALAGOLI, ESAB SPA., MESERO, ITALY.<br />

Gas de France completed the expansion of<br />

their LNG receiving and distribution terminal in<br />

Fos Cavaou, near Marseille, in mid-2007. The<br />

project, awarded to a joint venture of Saipem<br />

and Sofregaz, comprised the engineering,<br />

procurement and construction of the overall<br />

terminal facilities, including three 110,000m 3<br />

LNG storage tanks, sub-contracted to the<br />

Italian Bentini Group SpA. whom relied on<br />

ESAB LNG welding technology.<br />

The Bentini SpA Group<br />

Established in the 1950s, the Bentini Group SpA,<br />

based in Faenza, Italy, expanded rapidly during<br />

post-war reconstruction, operating abroad as<br />

from 1976, and enjoying continuous growth and<br />

diversification in the civil and industrial<br />

plant-engineering sector, both as a main and sub<br />

contractor. It has a turnover of 150 million Euros<br />

and over 1200 employees, operating in France,<br />

Algeria, Libya and Nigeria. In Algeria, it has two<br />

daughter companies; Gepco SpA, a general<br />

contractor in the oil and gas industry, and Benco<br />

SpA, a general construction contractor.<br />

LNG tanks<br />

The project consisted of three cryogenic tanks,<br />

each with a capacity 110,000m 3 . They are<br />

cylindrical in shape with a diameter of 80m and<br />

an overall height of 37m. The maximum liquid<br />

level inside the tank is 24m. The inner wall (in<br />

contact with the liquid gas) is constructed from<br />

X8Ni9 steel (EN 10028-4) - a 9% nickel steel,<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 15

typically for cryogenic applications down to<br />

-196°C. Here the liquefied natural gas, arriving in<br />

LNG tankers, is stored and held at a temperature<br />

of -163°C at a pressure slightly above atmospheric.<br />

For distribution, the LNG is re-gasified by heat<br />

exchange with sea water, odorised and transported<br />

through the pipeline network at a pressure of<br />

70-100 bar.<br />

The thickness of the tank bottom plates is 6mm,<br />

and the stringer plate 10mm. The metal plates for<br />

the primary tank - in contact with the liquid - vary<br />

in thickness from 16.6mm (at the bottom) to<br />

12mm (at the top), compensating for the<br />

hydrostatic pressure from the stored liquid, which<br />

increases gradually towards the bottom. Figure 1,<br />

representing the tank cross section, gives an idea<br />

of the complexity and types of materials involved<br />

in the construction.<br />

Materials and welding<br />

The main component is the primary tank<br />

designed to contain the liquid natural gas. The<br />

primary tank is surrounded by a corner protection<br />

system - lower in height and designed to offer<br />

additional safety in the case of liquid leakage from<br />

the primary tank. These components are made<br />

from 9%Ni steel, resistant to temperatures down<br />

to -196°C (coloured red in Figure 1). Further protection,<br />

known as the vapour barrier and covering<br />

the whole tank internally, is made of carbon steel<br />

plates and serves to hold the gas in equilibrium<br />

with the liquid.<br />

According to Bentini’s Welding Engineer in<br />

charge, Mr. Emanuele Ceroni, “The welding was<br />

of vital importance – from the initial welding<br />

process qualifications right through to the on-site<br />

management and monitoring of the human<br />

resources - due to the importance of the<br />

construction and the potentially associated risks.<br />

The welding processes used for construction of<br />

the tank are MMA, SAW and semi-automatic<br />

GMAW. The latter process was used for welding<br />

the suspended aluminium roof with ESAB OK<br />

Autrod 5183 wire. For the vertical joints of the<br />

carbon steel vapour barrier, about 7500m for<br />

each tank, Saipem had proposed uphill MMA.<br />

The two phases in construction of the suspended<br />

roof and vapour barrier did not overlap. I, therefore,<br />

had the idea to also use the semi-automatic<br />

Figure 1. Cross section of the LNG storage tank.<br />

GMAW process for the vapour barrier, where it<br />

involved a fillet weld. After obtaining approval from<br />

Saipem we searched for the right consumable.<br />

ESAB advised us to use the vertical downhill<br />

technique with 1.2mm diameter Tubrod 14.12<br />

wire. In production, this wire allows an appreciable<br />

increase in productivity and consequent saving of<br />

time, as well as limited deformation.”<br />

As previously mentioned, various materials are<br />

involved in the construction, starting with the<br />

most strategic component, X8Ni9 steel (EN<br />

10028-4), with 9% nickel. It is steel typically used<br />

for cryogenic applications and has been widely<br />

used in this type of plant. However, as it is highly<br />

sensitive to magnetic fields, it could create<br />

potential problems associated with welding. This is<br />

the reason why the ESAB OK 92.55 electrode was<br />

chosen as it can also be used with AC to minimise<br />

the risk of magnetic arc blow. Most of the welding<br />

of the 9% nickel steel was done with these electrodes<br />

at a consumption of around 32 tons.<br />

1 – Piping from 114.3 to 762.0mm<br />

(mat. EN 10028-7 X2CrNi 18/9)<br />

2 – Compression ring<br />

(mat. EN 10028-3 P 355 NL1)<br />

3 – Outer reinforced concrete wall<br />

4 – Carbon steel vapour barrier<br />

(mat. EN 10028-3 P 275 NL1)<br />

5 – Main tank (mat. EN 10028-4 X8Ni9)<br />

6 – Insulation with perlite<br />

7 – Corner protection system<br />

(mat. EN 10028-4 X8Ni9)<br />

8 – Resilient blanket<br />

9 – Bottom, carbon steel vapour barrier<br />

(mat. EN 10028-3 P 275 NL1)<br />

10 – Bottom, secondary tank<br />

(mat. EN 10028-4 X8Ni9)<br />

11 – Bottom, primary tank<br />

(mat. EN 10028-4 X8Ni9)<br />

12 – Foundation<br />

13 – Suspended aluminium roof<br />

(mat. ASTM B 209 ALLOY 5083)<br />

14 – Stringer plate<br />

(mat. EN 10028-4 X8Ni9)<br />

A smaller quantity of wire and flux was used for<br />

submerged arc welding of the bottom plate with a<br />

suitable tractor and for circumferential welding<br />

with the ESAB Circomatic system, using<br />

ERNiCrMo-4 wire.<br />

In construction, carbon steel was used for the<br />

metal plates of the outer lining, P275NL1 steel<br />

(EN 10028-3) for the base and S 275 J2G3 (EN<br />

10025) for the entire roof structure. Also, part of<br />

the piping was made of ASTM A106 Gr. B steel.<br />

A total of 21 tons of ESAB Citobasico electrodes,<br />

2600kg of ESAB OK Tubrod 14.12 cored wire<br />

and modest quantities of OK Tigrod 12.60 for<br />

certain TIG welding operations were used.<br />

In addition, a high quantity of stainless steel<br />

piping in X2CrNi 18/9 (EN 10028-7) was welded<br />

with ESAB OK 61.35. ESAB OK 67.60 (309L)<br />

electrodes were used for the dissimilar joints<br />

between stainless steel and carbon steel, as well<br />

as for the joints between pipes and metal plates<br />

16 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

of the roof, involving an overall consumption of<br />

approximately 7-8000kg, in addition to 1400kg of<br />

ESAB OK Tigrod 16.10 rods.<br />

Finally, the suspended aluminium roof (Figure 1),<br />

made of ASTM B209 alloy 5083, was welded<br />

with the GMAW process using 1.2mm and<br />

2.4mm ESAB OK Autrod 5183 wire, total<br />

consumption being1500kg.<br />

Co-operation<br />

“Our relationship with ESAB is excellent”, says<br />

Emanuele Ceroni. “Throughout the project, we<br />

received full support in terms of presence,<br />

assistance, advice, competence and innovation,<br />

as in the case of the OK Tubrod 14.12 wire.<br />

ESAB lives up to its image in quality, supply<br />

and service.”<br />

ABOUT THE AUTHOR:<br />

NAAM BRUNO FUNCTIE. MALAGOLI IS PRODUCT MANAGER<br />

CONSUMABLES AT ESAB SPA., MESERO, ITALY.<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 17

SIF Group bv at the foundation of<br />

Dutch wind energy<br />

ESAB SAW technology crucial in the production of piles and<br />

transition pieces for the Q7 North Sea wind farm.<br />

ERIC DE MAN ESAB NEDERLAND B.V. THE NETHERLANDS AND WILLIAM LAFLEUR SIF GROUP BV THE NETHERLANDS<br />

Q7 is the largest offshore wind farm<br />

in the Dutch sector of the North Sea<br />

and a step forward in the<br />

Netherlands’ renewable energy<br />

policy to boost wind energy<br />

production to 2750 MW by 2020.<br />

Sif Group bv manufactured the<br />

foundation piles and the transition<br />

pieces.<br />

Source: Offshore Windpark Q7<br />

18 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

Figure 1. One of the monopiles being driven into the sea bed. The piles are 50 or 54 m in length and the water<br />

depth is 19-24 m. Source: Offshore Windpark Q7.<br />

Figure 2. Positioning of a transition piece onto a monopile.<br />

The transition piece reaches 15 m above sea level.<br />

Acknowledgement.<br />

We thank the management of Sif Group bv for<br />

facilitating our visit to the production site.<br />

The Q7 project<br />

The Q7 offshore wind farm has been built some<br />

23 km offshore from IJmuiden, in block Q7 of the<br />

Dutch continental shelf. It is unique in the sense<br />

that it is the world’s first located at such a distance<br />

from the coast (outside the 12-mile zone)<br />

and in deeper waters than ever before (19-24m).<br />

This was one of the reasons why its owners,<br />

sustainable energy group Econcern, and energy<br />

company ENECO Energie, selected the proven<br />

technology of the Vestas V-80 2.0 MW turbines.<br />

The project comprises 60 wind turbines with a<br />

total capacity of 120 MW.<br />

Under the Kyoto Protocol, The Netherlands<br />

agreed to reduce greenhouse gas emissions, in<br />

the period <strong>2008</strong>-2012, by 6% relative to the 1990<br />

levels. The Q7 project will contribute a reduction<br />

of 225,000 tonnes of CO 2<br />

emission, annualy.<br />

Van Oord, an international dredging and marine<br />

contractor, was responsible for the installation of<br />

the wind farm; offshore erections starting in May<br />

2007.<br />

The foundation piles (monopiles), 54 m long with a<br />

diameter of 4 m and 320 tons in weight, were<br />

driven into the sea-bed for over half their length.<br />

The transition pieces, weighing 115-tons and<br />

reaching 15 m above sea level, were placed onto<br />

the foundations using Jumping Jack, a<br />

specially designed vessel (Figures 1 & 2).<br />

The masts (105 tonnes), and the turbines (65<br />

tonnes), are produced by Vestas and shipped to<br />

IJmuiden for erection. Sea Energy – another<br />

dedicated offshore construction vessel<br />

– transported two wind towers and two turbines<br />

at a time to Q7 for installation.<br />

To minimise turbine interaction, guidelines<br />

stipulate that the turbines must be separated by a<br />

distance of at least 5 times their rotor diameter<br />

(5 x 80m). The Q7 turbines are placed apart at a<br />

distance of 550m.<br />

Van Oord was also responsible for the installation<br />

of a 520 ton transformer substation on a<br />

monopile in the middle of Q7 - the first offshore.<br />

Q7 will be fully operational in March <strong>2008</strong>.<br />

Sif Group bv<br />

Sif Group bv, located in Roermond, The<br />

Netherlands, specialises in the manufacture of<br />

heavy tubular structures for the offshore oil and<br />

gas industry, offshore windfarm foundations,<br />

harbour and jetty facilities, and pressure vessel<br />

shells and cones. The company has vast<br />

experience in welding, heat treatment and nondestructive<br />

and destructive testing of fine grained<br />

high strength structural steels commonly used in<br />

these industries. Sif Group bv is located on the<br />

river Maas with its own docking facilities and direct<br />

connections to strategically located main ports,<br />

such as Rotterdam and Antwerp, enabling them to<br />

ship structures of any dimension and weight, up to<br />

800 tons, using coasters or their own river barges.<br />

Anticipating the boom in offshore wind farms, Sif<br />

Group bv invested heavily in a new yard lay-out, a<br />

new production hall for foundation piles and<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 19

(+ flange) and the monopiles. The design temperature<br />

of the transition piece was -10°C (above<br />

LAT - Lowest Anticipated Tide) and 0° (below<br />

LAT) for the monopiles, whereas the lowest CVN<br />

test temperature was -50°C, valid for the thickest<br />

wall sections of the transition pieces. The<br />

construction was subject to GL Rules &<br />

Regulations IV Part 2: Regulations for the<br />

certification of Offshore Wind Energy Conversion<br />

Systems Edition 1999.<br />

Figure 3. Monopile under construction. Note the longitudinal en circumferential welds.<br />

modern production lines - a process that is still<br />

ongoing. This policy has been extremely successful,<br />

judging by the impressive list of offshore wind<br />

farms in Western Europe in which the company<br />

has been involved. More than 80% of the installed<br />

offshore wind farms rely on steel foundations<br />

fabricated by Sif Group bv, amongst them the<br />

Horns Rev project in Denmark (the second largest<br />

farm to date) and the Q7 project.<br />

Sif Group bv maintains an effective quality<br />

management system certified in accordance with<br />

the ISO 9001: 2000 standard and with the<br />

implementation of EN-ISO 3834-2 comprehensive<br />

quality requirements for welding. Additional<br />

international approvals and authorisations include:<br />

• Structural tubulars: API Spec. 2B<br />

• Pressure vessel parts: ASME U stamp, ASME<br />

U2 stamp, ASME S stamp, PED 97/23<br />

• Dynamically loaded Steel Structures:<br />

DIN 18800-7 Class E – Ü stamp.<br />

Dimensions, material grades and mechanical<br />

requirements.<br />

The challenging Q7 project involved the manufacture<br />

of 61 mono piles and 61 transition pieces<br />

(60 for the wind farm and one for the transformer<br />

station). Both are tubular structures; the monopiles<br />

are straight and the transition pieces slightly conical.<br />

Figure 3 shows a monopile under construction.<br />

The principal weld connections, the longitudinal<br />

and circumferential welds are clearly visible. The<br />

individual cans are 3–3.5m in length and 4m in<br />

diameter with the longitudinal welds staggered at<br />

180° intervals from can to can. The wall thickness<br />

varies over the length of the monopile, from 45mm<br />

for the thinnest section, to 86mm. Transitions<br />

between differing wall thickness were smoothed by<br />

chamfering (1:5) and/or weld build-up.<br />

Table 1 gives an overview of steel grades and<br />

CVN impact requirements for the several thickness<br />

ranges, both for the transition pieces<br />

Sif fabrication of monopiles and transition<br />

pieces.<br />

The production line starts with beveling by flame cutting<br />

or machining and subsequent cold rolling of<br />

plates to a ring section. With two bending machines,<br />

Sif Group bv can roll plate with a thickness of<br />

20-150mm to shells with a diameter of 0.6 to 8m<br />

and a maximum width of 4.2m (Figure 4). The rolling<br />

process is performed in several steps to achieve the<br />

specified dimensions and roundness; also to facilitate<br />

perfect alignment for high productivity welding.<br />

Tubular structures, in general, and monopiles, in<br />

particular, are straightforward constructions with<br />

heavy longitudinal and circumferential welds. SAW<br />

makes up more than 90% of all welding. Serial<br />

production depends on an efficient factory lay-out<br />

where fabrication is performed in a logical<br />

sequence, minimizing internal transportation of<br />

components. Factory lay-out is also important to<br />

achieve the full production potential offered by the<br />

Table 1. Material grades, thickness and impact requirements<br />

Application Thickness Structural<br />

Category<br />

Material<br />

grade specified<br />

Test<br />

temperature<br />

Impact energy<br />

energy requirements<br />

Transition shell<br />

T< 45 primary S355J2G3- -30°C 34J av. (L)<br />

Td = -10°C<br />

EN10025<br />

24J av. (T)<br />

45

equipment and the welding heads getting<br />

jammed by weld metal shrink (longitudinal welds)<br />

Submerged arc welding<br />

Another constant factor is the wire/flux combination.<br />

Sif Group bv generally uses ESAB OK Autrod<br />

12.32 solid wire for medium and high strength<br />

steels (EN756: S3Si) combined with a high basic<br />

flux (EN760: SA FB 1 55 AC H5).<br />

The combination yields good impact properties<br />

down to -60° and is ideal for the various<br />

multi-wire SAW processes applied by Sif Group bv.<br />

Essential is the good slag release, mostly selfdetaching,<br />

in the first runs of the narrow gap joints.<br />

Figure 5. Semi-narrow gap joint used for external longitudinal<br />

and circumferential joints.<br />

Figure 4. Rolling plates to shells; the first fabrication step<br />

in the production of monopiles.<br />

submerged arc welding process.<br />

Joint preparation is basically the same for all<br />

welds, with only the semi-narrow gap varying in<br />

depth, dependent on the wall thickness. It is similar<br />

for all heavy tubular constructions produced by<br />

Sif Group bv, be it monopiles, foundation piles for<br />

oil rigs, jacket legs or other components for the oil<br />

and gas industry. It makes production predictable,<br />

ensures reproducible weld quality and reduces<br />

the start-up times from project to project.<br />

The semi-narrow gap joints produced through the<br />

milling process are geometrically exact, smooth,<br />

even, and burr-free, their quality surpassing that<br />

of back-gouged joints. Furthermore it has the<br />

advantage that the root of the internal welds can<br />

be taken out, together with any weld imperfections,<br />

in this critical area of the joint (Figure 5)<br />

Narrow gap welding, of course, has the<br />

advantage of a reduced weld volume and, thereby,<br />

a shorter welding time per joint and reduced weld<br />

metal consumption. The option for a semi-narrow<br />

gap, with an included angle of 13°, was made to<br />

avoid access problems for the multi wire SAW<br />

OK Autrod 12.32 is supplied on specially<br />

designed bulk spools with 350 or 700kg of wire<br />

– known as spiders - designed to fulfill the specific<br />

Sif Group demands and only supplied to them<br />

(Figure 6). They are colour-coded, separating<br />

them from occasional other wire qualities supplied<br />

on spider, and wrapped in a protective foil that<br />

can remain on the spools without hindering the<br />

wire pay-off. The wire is spooled to discharge in<br />

the direction needed for the multi-wire SAW<br />

systems. The specification of OK Autrod 12.32 is<br />

very narrow in regard to chemical composition<br />

and surface condition - to fulfill offshore<br />

requirements.<br />

The special production line for the manufacture of<br />

wind turbine foundations consists of several multiwire<br />

submerged arc welding stations, most<br />

equipped with ESAB welding components and<br />

high duty LAF/TAF power sources. Sometimes<br />

ESAB and Sif Group BV cooperate in retrofitting<br />

existing column and boom-type stations or the<br />

provision of complete new automatic solutions.<br />

A recent example was a customer-designed SAW<br />

installation for welding of internal stiffener rings in<br />

tubular constructions.<br />

The portal welders, where the larger piles are<br />

completed, are huge and highly efficient (Figure 8).<br />

Circumferential welds are simultaneously welded<br />

by an operator controlled multi-wire station, the<br />

deposition rates thus achieved being impressive.<br />

The system is equipped with PLC controls and<br />

optical sensors, which monitor and control the<br />

entire welding process and guarantee a consistent<br />

and high weld quality. The operator starts the<br />

Figure 6. OK Autrod 12.32 supplied on customer<br />

designed spindles.<br />

Figure 7. Macro of a typical weld cross section in 70mm<br />

plate.<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 21

Table 2. Weld metal properties at -50°C in 70mm plate from a WPS comparable to the weld of figure 5.<br />

Cv-impact energy [J]<br />

Average<br />

1st welded side V-joint, SAW-twin 2 mm subsurface 111J 94J 90J 98J<br />

2nd welded side U-joint, SAW-triple 2 mm subsurface 110J 102J 104J 105J<br />

Root area 50 mm depth 112J 154J 150J 139J<br />

welding process manually and the system<br />

automatically completes the full welding sequence,<br />

including the positioning of split beads across the<br />

width of the joint. If necessary, the operator can<br />

change to manual control at any time.<br />

Figure 7 shows an example of an absolutely<br />

flawless heavy weld obtained in this manner. Weld<br />

metal properties at -50°C, from a related welding<br />

procedure qualification for Q7 in 70mm plate<br />

thickness, are given in table 2.<br />

Sif Group bv is particularly impressed with the<br />

performance of the ESAB wire feeders on the<br />

narrow gap equipment and the LAF 1250 and<br />

TAF 1250 power sources. The installation<br />

operates 24 hours a day, with minimal<br />

maintenance, and has not given a single problem<br />

over a period of 2 years.<br />

Figuur 8. Portal welder for circumferential welding, in operation.<br />

Sif Group bv Reference list of windfarm projects.<br />

• 1994 Medemblik, Netherlands 4 Monopiles Ø 3.500x35x28.000mm Weight 346 ton<br />

• 2002 Horns Rev, Denmark 80 Monopiles ø 4.000x50x58.000mm Weight 11.080 ton<br />

80 Transitions ø 4.240x35x15.000mm Weight 5.325 ton<br />

• 2003 North Hoyle, United Kingdom 30 Monopiles ø 4.000x30:70x58.000mm Weight 8.508 ton<br />

30 Transitions ø 4.200x35x12.300mm Weight 1.150 ton<br />

• 2003 Arklow, Ireland 7 Monopiles ø 5.000x50x45.000mm Weight 1.931 ton<br />

7 Transitions ø 5.390x45x15.150mm Weight 929 ton<br />

A bright future in wind energy<br />

By timely investment in new welding technology<br />

and production facilities, Sif Group bv has been<br />

able to gain a strong foothold in the Western<br />

European offshore wind energy market and made<br />

a major contribution to the generation of clean<br />

energy. The project list at the end of this article<br />

highlights the company’s reputation as a reliable<br />

partner for large wind energy projects. With many<br />

new wind energy projects anticipated, the future<br />

looks bright. Partnered with ESAB for welding<br />

technology, the company can be assured of a<br />

supplier that understands its needs and can<br />

respond to its specific requirements.<br />

• 2004 Kentish Flat, United Kingdom 30 Monopiles ø 4.300x50x37.000mm Weight 5.013 ton<br />

30 Transitions ø 4.540x35x12.050mm Weight 1.823 ton<br />

• 2005 Barrow, United Kingdom 30 Monopiles ø 4.750x45:75x51.000mm Weight 11.320 ton<br />

30 Transitions ø 5.100x55x21.600mm Weight 3.460 ton<br />

• 2006 Burbo, United Kingdom 25 Monopiles ø 4.700x45:75x37.000mm Weight 5.307 ton<br />

25 Transitions ø 5.390x45:67x22.350mm Weight 3.994 ton<br />

• 2006 Beatrice, United Kingdom 2 sets Central Pipe, Legs & Pilesleeves Weight 832 ton<br />

8 Piles ø 1.869x60/80x42.500mm Weight 935 ton<br />

• 2006 Onshore Tripod Multibrid, Germany 1 Main column ø 6.000x35:75x26.000mm Weight 203 ton<br />

3 Pileguides ø 2.900x40:65 x 9.000mm Weight 102 ton<br />

• 2006 Q7, The Netherlands 61 Monopiles ø 4.000x35:79x54.000mm Weight 18.700 ton<br />

61 Transitions ø 4.200x35:57x19.000mm Weight 5.340 ton<br />

• 2007 Lynn & Inner Dowsing, UK 54 Monopiles Ø 4.740x50/75x36.000mm Weight 12.100 ton<br />

54 Transitions Ø 5.100x45/67x22.050mm Weight 9.100 ton<br />

ABOUT THE AUTHORS:<br />

ERIC DE MAN, BSC, EWE, IS PRODUCT MANAGER<br />

CONSUMABLES AND KEY ACCOUNT MANAGER AT<br />

ESAB NEDERLAND B.V., AMERSFOORT, THE<br />

NETHERLANDS.<br />

WILLIAM LAFLEUR, BSC, EWE, IS MATERIAL &<br />

WELDING ENGINEER AT SIF GROUP BV, ROERMOND,<br />

THE NETHERLANDS.<br />

22 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

Zorya-Mashproekt relies on ESAB for<br />

arc welding of gas turbine components<br />

YURIY BUTENKO, SE RPCGTI ZORYA-MASHPROEKT, NIKOLAEV, UKRAINE AND ALEXEY BELIKOV, ESAB RUSSIA, MOSCOW, RUSSIA.<br />

The Zorya-Mashproekt Gas Turbine<br />

Building Research and Production<br />

Complex is a leading Ukranian producer<br />

of industrial gas turbines<br />

and marine gas turbine power<br />

plants and engines. Although,<br />

today, naval demand is far from<br />

exhausted, particular emphasis is<br />

placed on the production of civil<br />

equipment. In the wake of associated<br />

technical developments, the<br />

company recently invested in<br />

state-of-the-art ESAB arc welding<br />

systems.<br />

The Zorya-Mashproekt Gas Turbine Building<br />

Research and Production Complex was founded<br />

in the early 1950s in Nikolaev, Ukraine, for the<br />

development and production of gas turbine<br />

equipment and reducers for vessels of the USSR<br />

Navy. In the 1970s, the company was assigned to<br />

develop and manufacture gas turbines for use in<br />

compressor stations on trunk gas lines and in<br />

mobile and stationary power plants. Over more<br />

than half a century, Zorya-Mashproekt has produced<br />

four generations of gas-turbine engines,<br />

used in around 500 battleships and commercial<br />

vessels. Twenty-four power plants, with a total<br />

capacity of 1120 MW, and over 500 gas compressor<br />

units, with a total capacity of more than<br />

6000 MW, are equipped with the company’s gas<br />

turbines.<br />

Today, Zorya-Mashproekt products compete with<br />

leading fabricators around the world, the main<br />

products being engines based on the DO71,<br />

DO90 and DO80 gas turbines with a capacity of<br />

6, 16 and 25 MW respectively. A new engine,<br />

DN70, with a capacity of 10 MW and an efficiency<br />

of 35%, is under development. It will replace<br />

technically outdated and less efficient turbines.<br />

Another development, demanded by the power<br />

generation industry, is a one-shaft engine with a<br />

capacity of 45-60 MW.<br />

ESAB assessment and advice<br />

Various steels and alloys are used in modern gas<br />

turbines, for example, CMn steels, low-alloyed<br />

steels, austenitic and martensitic stainless steels,<br />

high-alloyed steels and nickel-base alloys. Some<br />

components are made of titanium (eg, turbine<br />

fans). When producing turbine parts, minimum<br />

weight and maximum material utilisation are<br />

Figure. 1. Zorya-Mashproekt’s DN-80 25MW gas turbine.<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 23

Figure. 2. Welding with one of the automatic TIG stations.<br />

important factors. Most parts are manufactured<br />

using welding technologies and the welded joint<br />

is often the crucial element defining the operational<br />

capability of the part. Also, with the limited<br />

weldability of some of the materials used, the<br />

most important consideration for the welding<br />

specialist is the selection of the appropriate and<br />

most efficient welding process, equipment and<br />

consumables.<br />

Electron-beam welding is the principal welding<br />

process used in the fabrication of gas-turbine<br />

engines. It is performed under vacuum, which<br />

protects the weld pool and facilitates weld metal<br />

strength, deformation being minimal due to the<br />

highly concentrated heat source. However, for many<br />

components, arc welding processes are preferred.<br />

Co-operation with ESAB began in 1995, when<br />

company management set the task of increasing<br />

production output and reducing welding costs.<br />

ESAB specialists carried out a technical audit of<br />

the welding methods used in production. Its<br />

conclusion was that, without up-to-date arc<br />

welding technologies - MMA and manual TIG<br />

welding being the main arc welding processes –<br />

results were high weld metal consumption and<br />

unnecessarily low overall productivity.<br />

Also, repair rates were high because the superior<br />

weld quality standard was hard to meet - even by<br />

qualified welders.<br />

The audit resulted in a recommendation for<br />

investment in programmable automatic TIG<br />

systems, programmable pulse inverter power<br />

sources and the replacement of MMA welding by<br />

MIG/MAG and cored wire welding (FCAW),<br />

wherever possible. In response to this, Zorya-<br />

Mashproekt acquired two ESAB automatic TIG<br />

systems, consisting of a MKR-300 column &<br />

boom, A 25 TIG welding head and A2 Minimaster<br />

GMAW head, PEG1 control unit, AristoMig 500<br />

power source (today named AristoMig 5000i) and<br />

PEMA-1500 positioners. For manual welding, the<br />

company bought various AristoMig 500<br />

multi-process inverters with U8 control unit – one<br />

machine covering MMA, TIG, MIG/MAG and FCAW.<br />

Automatic TIG<br />

Automatic TIG welding is used for the circumferential<br />

and longitudinal welds in gas turbine<br />

bodies in 3-8 mm thick austenitic or martensitic<br />

stainless steel or nickel-base alloys. It involves<br />

pulsed TIG welding of I-joints without a root gap,<br />

onto a copper backing bar, and without filler<br />

material addition. Plate thicknesses up to 3 mm<br />

are welded one-sided and, above 3 mm, two-sided.<br />

Argon is both shielding and backing gas – the<br />

latter flowing into the root area through holes in<br />

the backing bar. Special devices ensure tight<br />

clamping of the weld edges onto the backing bar.<br />

Welding parameters and sequence are pre-programmed<br />

in the control unit, for the various materials<br />

and plate thicknesses. Table 1 gives an<br />

example of actual parameter settings and Figure<br />

3 shows a weld deposited with these parameters.<br />

This method has a number of advantages, in<br />

addition to a dramatic increase in productivity.<br />

By fully controlling the arc, the quality and<br />

Table 1. Parameters for automatic pulse TIG welding of<br />

steel (347) with 3 mm wall thickness.<br />

No Parameters of welding mode Value<br />

1. Pulse current, A 210<br />

2. Background current, A 40<br />

3. Pulse duration, sec. 0.40<br />

4. Inter-pulse time, sec. 0.42<br />

5. Upslope, sec. 0.1<br />

6. Downslope, sec. 0.8<br />

7. Gas pre-flow, sec. 1.0<br />

8. Gas post-flow, sec. 5.0<br />

9. Travel speed, cm/min 18<br />

10.<br />

Consumption of argon for gas<br />

shielding, l/min.<br />

11.<br />

Consumption of argon for gas<br />

backing, l/min.<br />

4<br />

12. Arc length, mm 2<br />

13.<br />

Diameter of tungsten electrode,<br />

mm.<br />

8<br />

4.0<br />

Table 2. Consumables classifications.<br />

EN<br />

SFA/AWS<br />

FILARC PZ6166 12073: T 13 4 M A5.9: EC410NiMo<br />

OK Tubrod 14.31 12073: T 19 12 3 L R M 3 A5.22: E316LT0-1, E316LT0-4<br />

OK 68.25 1600: E 13 4 B 4 2 A5.4: E410NiMo-15<br />

OK 63.30 1600: E 19 12 3 L R 12 A5.4: E316L-17<br />

Figure. 3. Appearance of a weld deposited by automatic TIG welding with the<br />

parameters of Table 1.<br />

24 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

25 ±2° 25 ±2°<br />

4 +1<br />

ring<br />

copper backing bar<br />

Figure 4. Joint preparation of a ring for the outlet part of<br />

a turbine.<br />

Figure 5. Flux-cored arc welding of an outlet ring, using FILARC PZ6166 and the AristoMig 500 inverter power source.<br />

appearance of the weld become consistent and<br />

repeatable. Also, the lower heat input from pulse<br />

welding gives lower welding stresses and<br />

consequently lower deformation, as well as a<br />

reduced risk of hot cracking in sensitive materials.<br />

As mentioned, the method allows welding without a<br />

root gap and without filler materials, but it places high<br />

requirements on the preparation of the weld edges:<br />

• the cut, achieved by laser cutting, must be<br />

exactly perpendicular to the surface;<br />

• after cutting, machining of the edges is required<br />

to a depth of 0.5 mm to remove the oxide film;<br />

• the joint area must be cleaned to metal shine<br />

(10-15 mm from both edges);<br />

• the plate edges must be square along the full<br />

length, without edge rounding and bevels;<br />

• the root gap may not exceed 0.2 mm;<br />

• the displacement and thickness variation of the<br />

plate edges may not exceed 10% of the<br />

nominal thickness;<br />

• run-on and run-off plates must be of the same<br />

material and thickness as the base metal.<br />

• the axis of the joint should coincide with the<br />

axis of the forming groove.<br />

Cored wire welding<br />

Flux- and metal-cored wires are widely used for<br />

manual and mechanised welding. FILARC<br />

PZ6166 metal-cored wire, sometimes combined<br />

with the MMA electrode OK 68.25, is used for<br />

components in martensitic stainless steel. For<br />

austenitic 18Cr-9Ni grades, the company uses<br />

OK Tubrod 14.31 rutile flux-cored wire and the<br />

MMA electrode OK 63.30 (Table 2).<br />

An example of cored wire welding with FILARC<br />

PZ6166 are the rings for the turbine outlet. These<br />

are in martensitic stainless steel 20-13 (410) with<br />

14-20 mm wall thickness, a diameter 600-800<br />

mm and a height up to 250 mm. After having<br />

rolled a bar to a ring, the ring is closed by manual<br />

welding in the downhand position.<br />

Welding is carried out with FILARC PZ6116 -<br />

1.2 mm, using the AristoMig 500 inverter power<br />

source. The 98%Ar/2%CO 2<br />

shielding gas gives a<br />

good weldability and limited burn-off of alloying<br />

elements, while leaving behind a relatively clean<br />

weld. The joint preparation is shown in Figure 4.<br />

The component is pre-heated to 200-220°C.<br />

The weld is started and finished on run-on and<br />

run-off plates with the same joint preparation and<br />

connected to the ring by strong tack welds. The<br />

root pass is welded onto a copper backing bar<br />

and the joined is filled with 5-8 passes, depending<br />

on the thickness. Each deposited stringer<br />

bead must be clear of oxides and the, usually<br />

small, amount of slag. The deep and wide penetration<br />

provided by PZ 6166 reduces the risk of<br />

lack of penetration and slag inclusions.<br />

The welding parameters used are:<br />

• stick-out length 15 mm<br />

• welding current 250 A<br />

• arc voltage 30 V<br />

• wire feed speed 11 m/min.<br />

These parameters provide a deposition rate of<br />

about 4.5 kg/h, increasing productivity considerably<br />

when compared with previously used MMA.<br />

Stable processes, consistent quality,<br />

increased productivity<br />

During the implementation phase, ESAB demo<br />

welders trained Zorya Mashproekt welders to<br />

operate the new systems and apply the welding<br />

methods. The welding processes are stable<br />

and problem-free. Inspection of the welded joints<br />

visually, by measurement and by x-ray, consistently<br />

reveals extremely low defect rates. ESAB welding<br />

technology has enabled Zorya Mashproekt to<br />

increase overall welding productivity, improve<br />

quality and simplify operations for welders. This<br />

positive experience has led the company to order<br />

new ESAB equipment, year on year, in particular<br />

AristoMig 500 inverter power sources.<br />

ABOUT THE AUTHOR:<br />

YURIY BUTENKO IS CHIEF WELDING SPECIALIST AT SE<br />

RPCGTI ZORYA-MASHPROEKT, NIKOLAEV, UKRAINE,<br />

A POSITION HAS HELD SINCE 1995. ALEXEY BELIKOV ,<br />

HAS BEEN PRODUCT MANAGER AT ESAB RUSSIA IN<br />

MOSCOW, SINCE 1994.<br />

<strong>Svetsaren</strong> no. 1 - <strong>2008</strong> - 25

26 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>

A complete and reliable partner<br />

for pipe mills.<br />

The latest ESAB equipment and consumables<br />

for longitudinal welding.<br />

EGBERT SCHOFER, ESAB AB, LAXÅ, SWEDEN AND MARTIN GEHRING, ESAB AB, GOTHENBURG SWEDEN.<br />

The demand for SAW-welded<br />

pipes has grown steadily over<br />

many years, with a significant<br />

increase in both 2006 and 2007.<br />

Worldwide, more than 150 pipe<br />

mills produce an estimated<br />

30,000,000 tonnes of SAW welded<br />

pipes. When this production is split<br />

between longitudinal and spiral<br />

welded pipes, we see a ratio of<br />

around 57/43%. ESAB is an established,<br />

reliable partner in the pipe<br />

mill segment, offering flux and wire<br />

as well as equipment components<br />

and controls.<br />

When it comes to welding equipment for the pipe<br />

mill industry, ESAB is known to have delivered<br />

hundreds of highly efficient power sources,<br />

very strong wire feeders, special internal and<br />

external welding heads and customised process<br />

controllers. ESAB is particularly strong in the<br />

retrofit business, boosting the productivity of<br />

existing lines by increasing the amount of wires,<br />

both internally and externally, and also by<br />

exchanging old controls for new process<br />

controllers, including data logging and interface to<br />

local network systems.<br />

Nevertheless, ESAB has never attempted to offer<br />

complete production lines. The company’s aim is<br />

clearly to stay in welding – ESAB’s core business.<br />

However, the drastically increased demand in<br />

SAW pipe welding, and our customers’ desire to<br />

reduce the number of suppliers, has made ESAB<br />

strengthen its focus on the segment and extend<br />

its range of products with, for example,<br />

specialised internal booms and advanced return<br />

current systems.<br />

Here, a number of new products are highlighted.<br />

They have been supplied exclusively to key<br />

customers for longitudinal pipe welding<br />

applications - although their benefits are equally<br />

valid for spiral welding.<br />

Continuous tack welding equipment<br />

Once rough formed, pipe coming out of the forming<br />

machine, can be tack welded by ESAB’s<br />

continuous tack welding equipment. The tack<br />

welding process itself is GMAW with solid wire of 3<br />

or 4mm diameter under CO 2<br />

or a mixture of CO 2<br />